Argentina Iron Ore Grinder Mill

.jpg)

CITIC Censa ships three large SAG mill shells for

2023年11月14日 Grinding mill shell specialist CITIC Censa recently shipped three complete SAG mill shells (in six sections) from its facility in Pontevedra, Spain to Lundin Mining’s Josemaria coppergold mine, located in the province 2024年11月26日 The dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile oregrinding plant the OGPmobile Mills for minerals and ores LoescheIron ore production in Argentina saw a steep increase in recent years In 2021, production stood at approximately 35 million metric tons, an increase of more than 40 percent in comparison toArgentina: iron ore production 2021 Statista2024年2月2日 FLSmidth has a longstanding history in supplying dry grinding solutions and has a marketleading position with over 80 sites operating more than 150 FLSmidth dry grinding FLSmidth to deliver a dry grinding solution to an iron ore

Reliable equipment for iron ore mines FLSmidth

For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops Automation, 2015年4月1日 In this study, a coarse sample of iron ore was tested in a pilot scale grinding circuit with a vertical mill Other three samples of pellet feed had already been tested with the Vertical mill simulation applied to iron ores ScienceDirect2020年3月28日 Modern iron ore pelletizing process operations may be divided into two main process sections: feedstock preparation and agglomeration processes In most plants, the Development of a Novel Grinding Process to Iron Ore2020年5月28日 The new approach is adapted to identify the retention time (RT) of the iron ore in the mill, and the total RT taken for the blend sample in the Bond’s ball mill is considered as the reference grinding time for milling in the Investigation on Iron Ore Grinding based on

.jpg)

Comparing strategies for grinding itabirite iron ores in

2021年3月15日 AG/SAG milling is technically feasible for grinding itabirites Closed singlestage circuit was the most attractive in terms of grinding efficiency Pebble crushing increased 2024年11月28日 Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to wheel speed of 14 rpm The stamps, 6½ by 7½ in by 14 ft in dimensions, weigh 450 to 500 lb including the castiron shoe The mills are usually built with three stamps to the mortar box and as many as three sets (nine stamps) per FLOOR MOUNTED LABORATORY GRINDING MILLGrinding The primary grinding mill grinds the material before it undergoes spiral gravity separation Efficient grinding means that there will be minimal recirculation material from a cyclone cluster or screening after milling, which decreases the The six main steps of iron ore processing2022年3月19日 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particlesGrinding iron ore concentrate by using HPGR and ball mills

.jpg)

Consumption of steel grinding media in mills – A review

2013年8月1日 Likewise, Hebbar (2011) has studied the grinding wear behaviour of austempered ductile iron as media material in the comminution of Kudremukh haematite iron ore in a ball mill The grinding experiments were conducted under different pH conditions, ie pH = 70 and pH = 85, while keeping other parameters fixed, at a mill speed of 74 rpm for 1 hr2020年3月28日 Based on batch grinding method and normalization idea, a conical ball mill is used and a quantitative separation method of grinding characteristics of multicomponent complex ore is proposedDevelopment of a Novel Grinding Process to Iron Ore 2014年1月1日 An analysis of the kinetics of dolomite grinding in a dry ball mill reveals that the following approximations apply for the parameters of the batch grinding model: the size discretized selection Population balance model approach to ball mill optimization in iron ore Our luxury castiron salt and pepper mills use a crank handle design for effortless grinding featuring coral red Free US Shipping We offer FREE standard shipping on all orders above £50 to a UK address (5 days)The Coral Mill CastIron Salt Pepper Grinders IronMills

.jpg)

SBM Ultrafine Powder Technology Industrial Grinding Mill,

In the Iron Oxide Grinding Production Line, HGM80 ultrafine mill is used to process 1250 mesh iron oxide powder, with an hourly output of 12 tons 2024 1120 Raymond Grinding Mill for Coal Powder Making PlantOur luxury castiron salt and pepper mills use a crank handle design for effortless grinding featuring coral red Free Shipping to Australia We offer FREE standard shipping on all orders above £50 to a UK address (5 days)The Coral Mill CastIron Salt Pepper Grinders IronMills2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function The paper demonstrates the application of this methodology to optimize solids concentration in Optimization of Solids Concentration in Iron Ore Ball Milling 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process Control

.jpg)

Energy conservation and consumption reduction in grinding

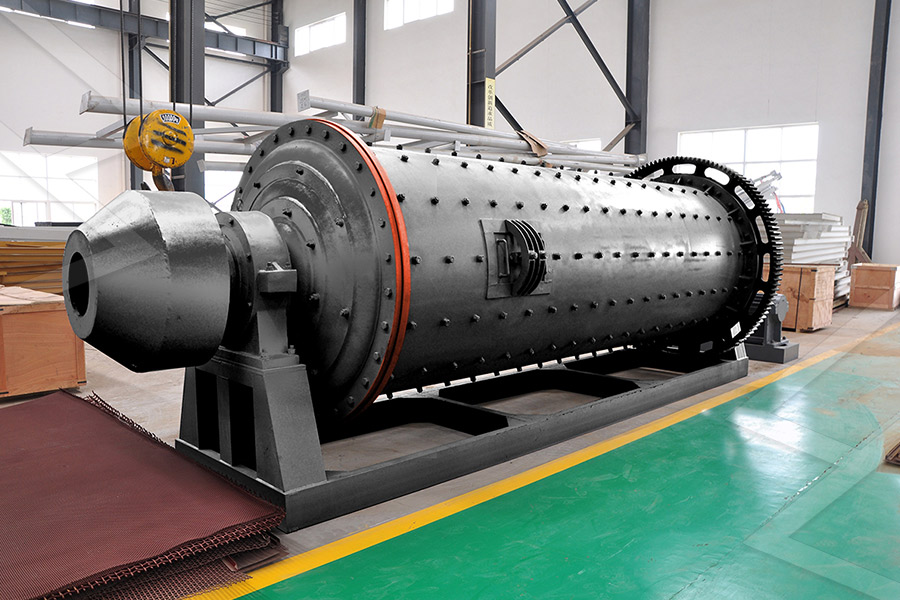

2023年11月1日 This paper demonstrates the feasibility of using a ceramic medium stirring mill to reduce the energy consumption of grinding operations through an industrial verification experiment Compared with the original twostage ball milling process, the cost of grinding power consumption is significantly reduced by about 5016%, which provides a reference for the 2017年2月20日 All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material When choosing primary autogenous grinding, run of mine ore up to 200300 mm in size is fed to the mill When iron contamination is detrimental, porcelain or natural nonmetallic materials are Grinding Mill Design Ball Mill Manufacturer2024年1月2日 Population balance model approach to ball mill optimization in iron ore grinding Patricia M C Faria1,2, Luís Marcelo Tavares2 and Raj K Rajamani3 1 Vale SA, Brazil 2 Department of Population balance model approach to ball mill 2009年1月1日 Also, equipment like ball mill is used at the final stages of grinding Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of Processing of Magnetite Iron Ores–Comparing Grinding Options

Multicomponent modeling and simulation of the Minas Rio iron ore

2022年8月24日 The increase in metal and reduction of ore grade in mineral deposits provide several challenges for ball milling circuit of lowgrade itabirite iron ore at the MinasRio operation (Anglo American These mills have the ability to adapt to the processing demands of ores with varying degrees of hardness By making adjustments to the grinding media and the duration of the grinding process, the mills can achieve the necessary level of fineness In the context of iron ore processing, ball mills serve a dual purposeThe role of ball mill in iron ore processing Grinding Mill2023年7月20日 According to the ore discharging method, the grinding mill is divided into overflow type, grating type, and peripheral discharging type According to the different grinding medium, the grinding mill is divided into three types: (1) ball mill – it is used widely, and almost all materials can be triturated by ball mill; (2) rod mill – its Ore Grinding SpringerLink2014年11月1日 In this study, a coarse sample of iron ore was tested in a pilot scale grinding circuit with a vertical mill Other three samples of pellet feed had already been tested with the methodology used (PDF) Vertical mill simulation applied to iron ores

.jpg)

Reliable equipment for iron ore mines FLSmidth

For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops Automation, digitalization and use of the latest technology in everything from bulk materials handling stockyard machines to crushers, screens and samplers give you the highest 2024年11月27日 A ball mill is an efficient grinder to grind ores like copper, gold, iron, chromite, and lithium, cement materials like limestone, clinker, and phosphate rock for fertilizer iron ore, silver ore, zinc ore, tungsten ore, and Highquality Ball Mill with Low price for Kinds of 2015年3月15日 The grinding parts of a Loesche mill (Fig 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring systemBetween the working surfaces of track and rollers, particle bed comminution takes place A dynamic air separator (3) is located above the grinding chamber, Research of iron ore grinding in a verticalrollermill2020年5月28日 The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore Grinding experiments were conducted according to Bond’s standard test procedure []For each iron ore sample, the RT taken to produce 250% circulating load in the BBM was Investigation on Iron Ore Grinding based on Particle Size Distribution

.jpg)

The Coral Mill CastIron Salt Pepper Grinders IronMills

Our luxury castiron salt and pepper mills use a crank handle design for effortless grinding featuring coral red Free UK Shipping We offer FREE standard shipping on all orders above £50 to a UK address (5 days)2021年11月1日 The present work analyzes the application of the UFRJ mechanistic ball mill model to grinding of iron ore pellet feed in an industrial grinding circuit In order to address the challenge of applying the model to a reasonably fine feed, selected model parameters were backcalculated on the basis of batch grinding tests The model is then used to Mechanistic modeling and simulation of grinding iron ore Our mills are easy to care for Please follow the instructions below to maximise their working life 1 Please do not put salt in our pepper millsThe grinding components don't have the same corrosionresistant coating as our salt mills, and they may rustThe Anthracite Mill Quality Cast Iron Salt Pepper GrindersThe selection of is according to customers’ requirements and the nature of the minerals Ore grinding can be divided into grinding with media and without It can also be divided into dry grinding and wet grinding SBM can offer ball mill, raymond mill, roll mill used as iron ore grinding machine These iron ore milling equipment can be used SBM Iron ore grinding plant for ores milling process unisbm

(PDF) Grinding Media in Ball MillsA Review ResearchGate

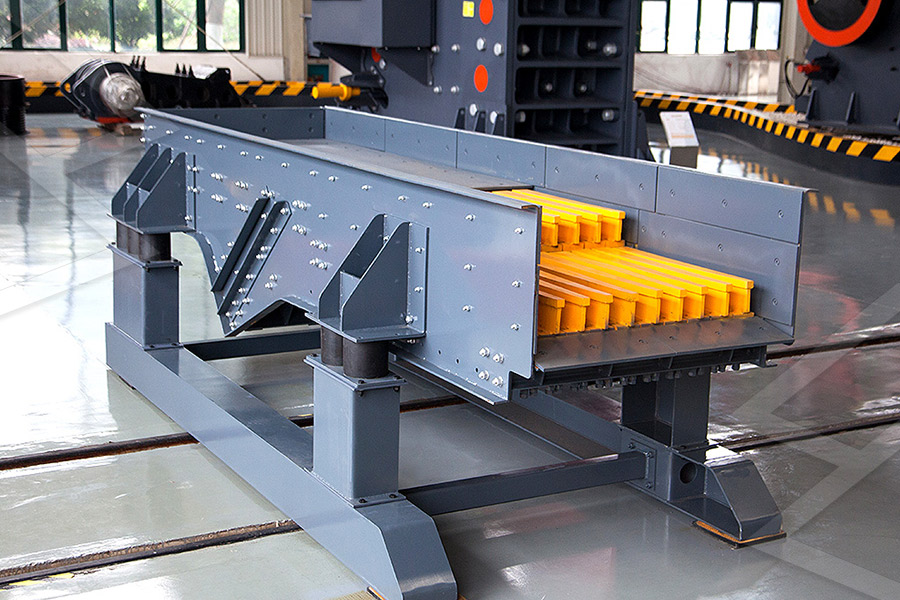

2023年4月23日 grinding media in a grinding mill with about 2630 wt% chrome by Chen et al [37] using a phosphate ore in a modified ball laboratory ball mill whose electrochemical potential could be controlled2021年1月14日 energy required which in this case was to grind the ore represented by the samples, from a feed size F80 of 152 mm to 80% passing 17 mm, and a simple adjustment procedure in case the SAG product size needed to be adjusted Bond rod and ball mill work indices are readily converted to pinion energy for rod and ball mills but not for SAG parison of Ore Hardness Measurements for 2024年11月28日 Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to wheel speed of 14 rpm The stamps, 6½ by 7½ in by 14 ft in dimensions, weigh 450 to 500 lb including the castiron shoe The mills are usually built with three stamps to the mortar box and as many as three sets (nine stamps) per FLOOR MOUNTED LABORATORY GRINDING MILLGrinding The primary grinding mill grinds the material before it undergoes spiral gravity separation Efficient grinding means that there will be minimal recirculation material from a cyclone cluster or screening after milling, which decreases the The six main steps of iron ore processing

Grinding iron ore concentrate by using HPGR and ball mills

2022年3月19日 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particles2013年8月1日 Likewise, Hebbar (2011) has studied the grinding wear behaviour of austempered ductile iron as media material in the comminution of Kudremukh haematite iron ore in a ball mill The grinding experiments were conducted under different pH conditions, ie pH = 70 and pH = 85, while keeping other parameters fixed, at a mill speed of 74 rpm for 1 hrConsumption of steel grinding media in mills – A review2020年3月28日 Based on batch grinding method and normalization idea, a conical ball mill is used and a quantitative separation method of grinding characteristics of multicomponent complex ore is proposedDevelopment of a Novel Grinding Process to Iron Ore 2014年1月1日 An analysis of the kinetics of dolomite grinding in a dry ball mill reveals that the following approximations apply for the parameters of the batch grinding model: the size discretized selection Population balance model approach to ball mill optimization in iron ore

The Coral Mill CastIron Salt Pepper Grinders IronMills

Our luxury castiron salt and pepper mills use a crank handle design for effortless grinding featuring coral red Free US Shipping We offer FREE standard shipping on all orders above £50 to a UK address (5 days)In the Iron Oxide Grinding Production Line, HGM80 ultrafine mill is used to process 1250 mesh iron oxide powder, with an hourly output of 12 tons 2024 1120 Raymond Grinding Mill for Coal Powder Making PlantSBM Ultrafine Powder Technology Industrial Grinding Mill, Our luxury castiron salt and pepper mills use a crank handle design for effortless grinding featuring coral red Free Shipping to Australia We offer FREE standard shipping on all orders above £50 to a UK address (5 days)The Coral Mill CastIron Salt Pepper Grinders IronMills2019年6月18日 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function The paper demonstrates the application of this methodology to optimize solids concentration in Optimization of Solids Concentration in Iron Ore Ball Milling